- This topic is empty.

-

AuthorPosts

-

2025-09-18 at 5:07 pm #7320

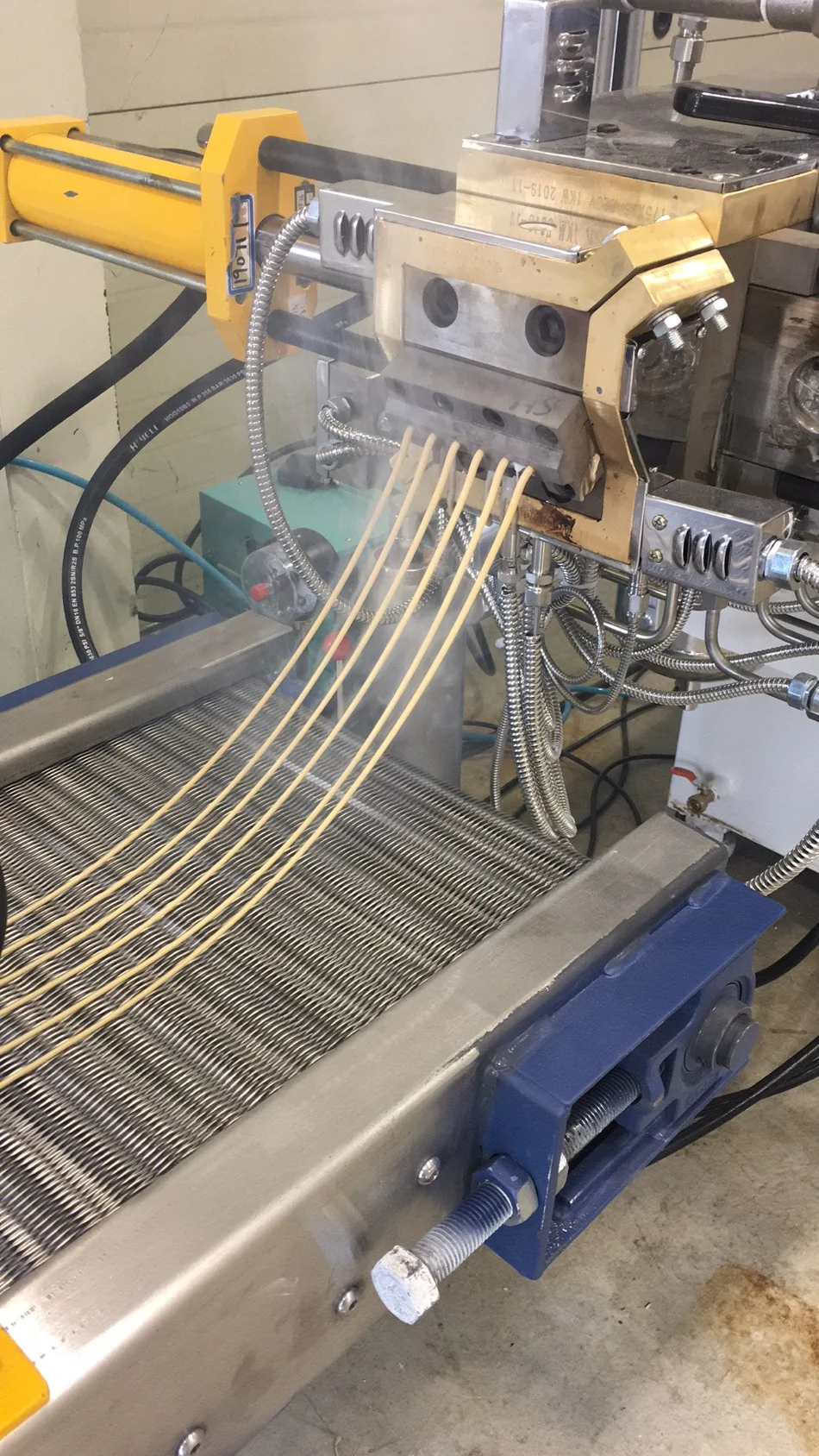

In the plastics industry, pelletizing is a critical step that directly affects product quality, consistency, and production efficiency. Among the many pelletizing technologies available today, the air cooling strand pelletizer system has become a preferred solution for manufacturers involved in extrusion, compounding, and plastic modification. Its ability to deliver clean, uniform pellets with stable performance makes it ideal for high-volume production lines.

As an industry leader, Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. is committed to driving innovation in mechanical manufacturing. With extensive expertise in foam extrusion, plastic compounding, and intelligent equipment design, the company provides advanced pelletizing systems tailored to meet the diverse needs of global customers.

So, how do you choose the right air cooling strand pelletizer system for your production line? Here are the key factors to consider.

1. Understand Your Material and Application

The first step is to analyze the type of polymers and additives you process. Different materials—such as PP, PE, ABS, PET, or engineering plastics—have specific melting points, cooling requirements, and cutting properties. Selecting a pelletizer designed for your target material ensures smooth operation and consistent pellet size.

2. Evaluate Cooling Efficiency

Unlike water-cooled systems, air cooling strand pelletizers rely on airflow to solidify and cool polymer strands before cutting. This method avoids moisture-related problems and is especially suitable for hygroscopic materials. Look for systems with optimized airflow design to achieve rapid and uniform cooling, ensuring pellet quality without surface defects.

3. Consider Pellet Size and Shape Requirements

Pellet uniformity is critical for downstream processing such as molding or extrusion. Choose a pelletizer with adjustable cutting speeds and precision knives to achieve the exact pellet dimensions your application demands. High-quality systems from Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. are designed for accuracy and repeatability, delivering consistent results across batches.

4. Assess Automation and Control Features

Modern production lines demand smart, automated solutions. An advanced air cooling strand pelletizer should include intelligent controls for speed adjustment, fault detection, and system monitoring. Automated strand feeding and cutting reduce manual intervention, improve safety, and enhance overall productivity.

5. Check Durability and Maintenance Needs

Durability is essential in high-output environments. Pelletizer components such as cutting blades, rollers, and cooling channels should be made from wear-resistant materials. Easy-to-clean designs also help minimize downtime and simplify routine maintenance. Choosing a trusted manufacturer ensures long-term reliability and service support.

6. Match Capacity with Production Goals

Every production line has different throughput requirements. Selecting a pelletizer system that matches your capacity needs helps balance efficiency and cost-effectiveness. Jiangsu Kaifeng Xinye offers a range of pelletizer models tailored for both medium and large-scale production, helping customers scale operations seamlessly.

Conclusion

An air cooling strand pelletizer system is a vital investment that can significantly improve production efficiency, product quality, and cost savings. By evaluating factors such as material type, cooling performance, pellet size, automation, and durability, you can identify the best system for your specific production line.

With its deep expertise in foam extrusion, plastic compounding, and intelligent manufacturing solutions, Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. continues to lead the industry by delivering high-quality, innovative pelletizing equipment. Their advanced systems help manufacturers achieve precision, efficiency, and long-term success in a competitive market.

http://www.kaifengmachine.com

Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.