- This topic is empty.

-

AuthorPosts

-

2025-11-14 at 6:25 pm #7662

https://www.magicmag-tech.com/permanent-magnet-drives-pmd.html

In the air gap between permanent magnets and soft magnets, a quiet transmission revolution is unfolding within industrial and mining enterprises.

01 Technical Principles: A Revolution in Magnetic Coupling

The Permanent Magnet Drive (PMD), an energy-saving speed control device that uses magnetic fields to transmit torque, is triggering a transmission technology revolution in the industrial and mining sectors.

Fundamentals of Permanent Magnet Transmission

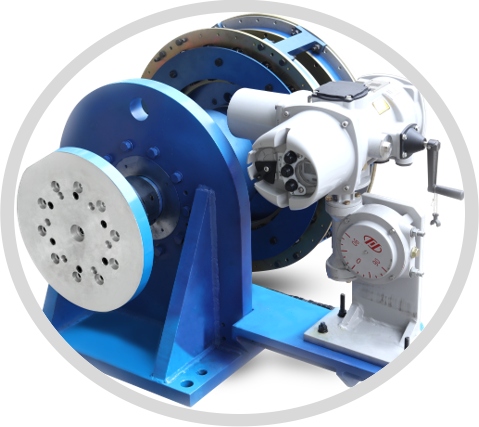

PMDs transmit torque by adjusting the air gap between the permanent magnet and the soft magnet. This non-contact magnetic soft connection fundamentally solves the wear and tear problems associated with traditional mechanical transmission.

When the motor rotates the conductor disc, the rotating magnetic field induces eddy currents in the permanent magnet, thereby transmitting torque. By adjusting the air gap between the permanent magnet and the conductor disc, stepless regulation of the output speed can be achieved.

Technical Advantages

Permanent magnet speed control technology demonstrates multiple advantages: high efficiency and energy saving, high reliability, adaptability to harsh environments, reduced system maintenance, and extended system service life.

Due to its non-rigid connection design, PMDs can effectively isolate vibration and noise, enabling soft starting and stopping of the motor load.

PMDs perform particularly well in energy saving. According to application case data, a single unit can save up to 909,000 kW·h of electricity annually.

02 Industrial and Mining Applications: Blossoming in Multiple Fields

Leveraging its unique advantages, permanent magnet speed control technology is showing broad application prospects in multiple scenarios within industrial and mining enterprises.

Mining Transportation

In the mining sector, permanent magnet technology is revolutionizing transport systems. The core power unit used in the nation's first rare earth permanent magnet rail car—the permanent magnet synchronous motor—has an efficiency increase of over 15% compared to traditional asynchronous motors, and its torque increases by 30% while its volume decreases by 50%.

In the renovation project of the belt drive system in the West Conveyance Lane of Zhaozhuang Coal Industry Company, four 1250kW permanent magnet synchronous motors were introduced. After the upgrade, the belt operating speed increased by approximately 39%, coal transport capacity improved by 25%, and operating energy consumption decreased by 12%.

Petrochemical Industry

In oil refining enterprises, permanent magnet speed control devices show great potential. In 2013, the Yanchang Petroleum project achieved smooth starting of high-voltage motors through a PMD system.

Permanent magnet speed control devices feature simple structure, reliable operation, and good environmental adaptability. They enable smooth stepless speed regulation and high speed control accuracy, making them particularly suitable for large-scale petroleum refining enterprises with high operational loads.

Power and Metallurgy

The power industry was a key early adopter of permanent magnet speed control technology. After the Jiaxing Power Plant applied PMD technology in 2008, equipment maintenance costs were significantly reduced.

After retrofitting the closed-loop water pump in a thermal power plant with a permanent magnet speed controller, the motor current decreased significantly, resulting in a high energy saving rate. After installing a permanent magnet speed controller on a high-temperature oxidizer induced draft fan, annual electricity savings reached 289,080 kWh, reducing CO2 emissions by 160.15 metric tons.

03 Innovative Breakthroughs: Dual Enhancement of Performance and Safety

As the application of permanent magnet technology deepens in industrial and mining enterprises, a series of innovative breakthroughs are occurring.

Performance Breakthroughs

The permanent magnet rail car developed by Baizheng Chuangyuan has reached its third generation. Test data shows its starting torque reaches 2.5 times the rated torque, and operating noise is reduced to 60 decibels.

In actual operation and maintenance, its maintenance-free permanent magnet motor reduces maintenance costs by 50%, key component replacement efficiency is improved by 40%, and the machine's 100,000-hour service life sets a new industry record.

Safety Innovations

"The core of this system lies in its 'four-layer safety protection'," Han Zhongliang explained, pointing to the control console: Full-range stepless speed control ensures stable equipment operation; four-quadrant variable frequency feedback technology achieves 100% recovery of braking energy.

The emergency braking system uses fail-safe brakes, building a solid last line of defense for the equipment. A 10-fold safety factor for core structural components makes the system more reliable.

Modular Design

The permanent magnet rail car uses a modular body structure that can be quickly assembled or disassembled like building blocks. The fully enclosed motor compartment adapts to harsh underground environments, extending the service life of the core drive components.

This design greatly simplifies on-site maintenance procedures and shortens equipment installation cycles.

04 Future Outlook: A Hundred-Billion-Yuan Market Opens Up

The application prospects of permanent magnet speed control technology in industrial and mining enterprises are vast, with huge market potential.

Favorable Policies

The "Guidelines for Intelligent Coal Mine Construction (2025)" issued by the Chinese government provides robust policy support for the intelligent transformation of industrial and mining enterprises. This permanent magnet power equipment, which integrates zero emissions, high safety, and low operating costs, precisely meets the demand for electrification in mining operations. With technological maturity and policy impetus, a market worth hundreds of billions of yuan is gradually unfolding.

Technology Integration

The deep integration of permanent magnet speed control technology with intelligent control systems is enhancing the level of intelligence in industrial and mining enterprises.

The new system at Zhaozhuang Coal Industry Company is equipped with an intelligent monitoring platform that can collect 12 key operating parameters in real-time, issue warnings, and initiate protection under abnormal conditions, having successfully averted potential failures multiple times.

Future Trends

Since the 2010s, China has gradually made breakthroughs in magnetic torque calculation and structural optimization design technology, promoting the integrated development of PMDs in the field of new energy equipment.

As of 2024, the maximum application power has reached 12MW-level wind turbines, indicating that permanent magnet speed control technology is continuously developing towards high power and high performance.

The effectiveness of Permanent Magnet Drives in industrial and mining enterprises is already evident. The upgraded belt system at Zhaozhuang Coal Industry Company has entered the phase of normalized operation, with relevant departments continuously monitoring operational data and optimizing operation and management measures.

The company is comprehensively summarizing and promoting the experience and results of this technological transformation, steadily advancing the upgrade of other production systems.

In the era demanding high efficiency and energy conservation, permanent magnet speed control technology, this green transmission solution, is becoming a vital force driving the transformation and upgrading of industrial and mining enterprises.

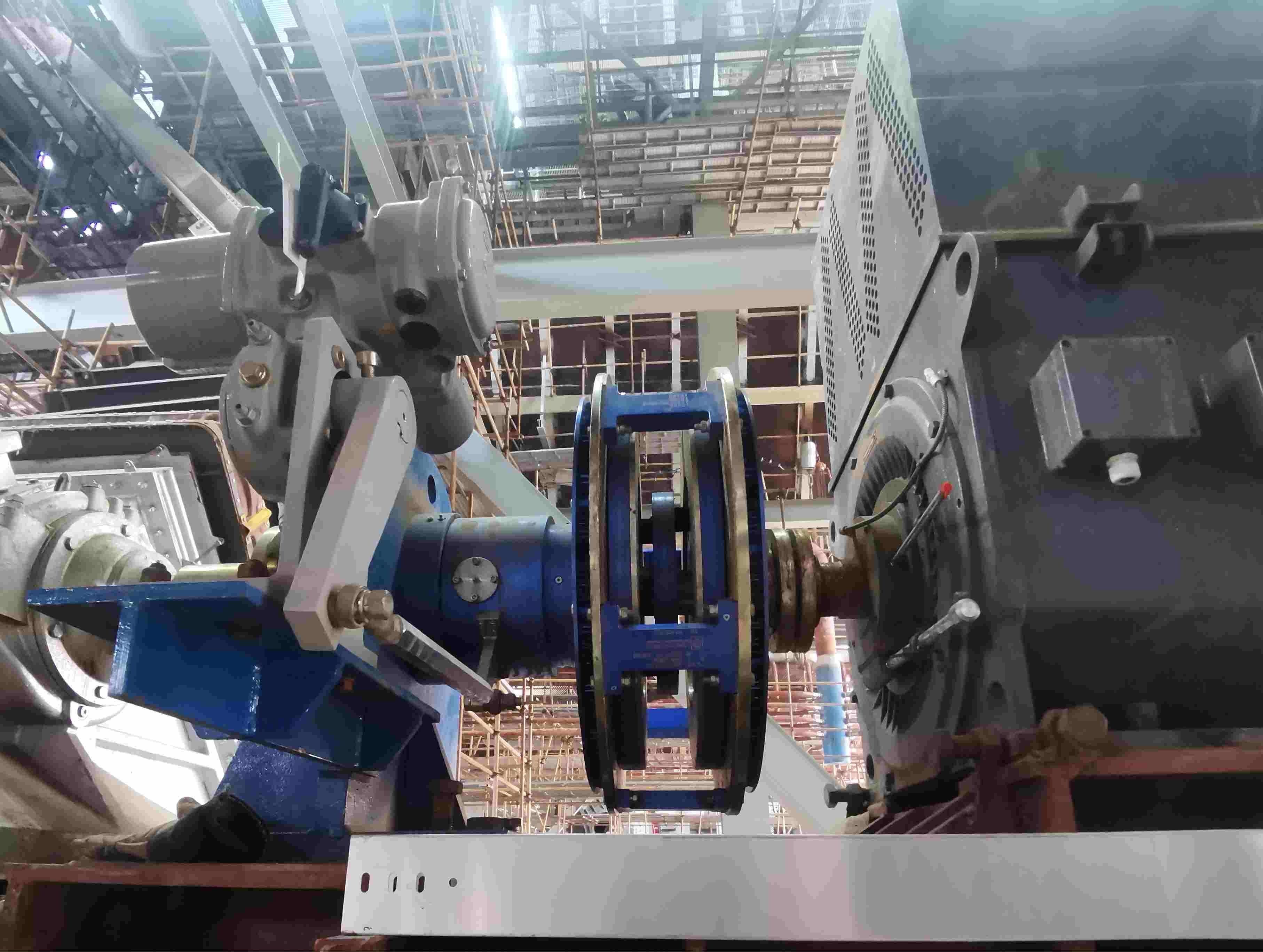

Application of MagicMAG 950kW PMD ASD Series on Exhaust Fan at Xin Guang Power Plant

Application of MagicMAG 650kW PMD ASD Water-Cooled Pump in Steel Plant

https://www.magicmag-tech.com/permanent-magnet-drives-pmd.html

SHANGHAI GAOLV E&M Technology Co.,Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.