- This topic is empty.

-

AuthorPosts

-

2025-12-22 at 5:19 pm #7907

Electrolytic copper foil has become one of the most critical materials in modern industries, especially in new energy applications such as lithium-ion batteries, 5G communications, and high-density printed circuit boards (PCBs). As demand for thinner, stronger, and more conductive foil continues to rise, manufacturers are investing heavily in advanced production technologies. Among these technologies, the electrolytic copper foil test line stands out as a vital tool for ensuring consistent quality and optimizing large-scale manufacturing.

This article takes an in-depth look at what an electrolytic copper foil test line is, how it functions, and why it plays a crucial role in producing high-precision copper foil. Additionally, we will highlight Timonic, an enterprise dedicated to the research and production of equipment for new energy lithium battery materials.

Understanding the Role of Electrolytic Copper Foil

Electrolytic copper foil is produced through an electrochemical deposition process, which allows manufacturers to create extremely thin and uniform layers of copper. This material is indispensable for lithium-ion battery current collectors, flexible circuit boards, and other advanced electronic applications.

The quality of the foil directly affects conductivity, mechanical strength, battery safety, and overall product performance. Any deviation in thickness, grain structure, or surface condition can compromise downstream manufacturing. This makes precision control essential—and that is where the test line becomes indispensable.

What an Electrolytic Copper Foil Test Line Does

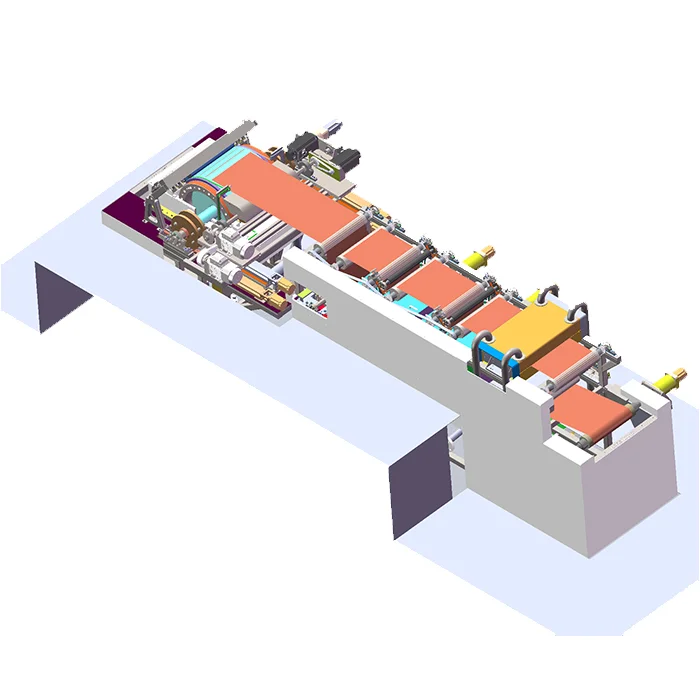

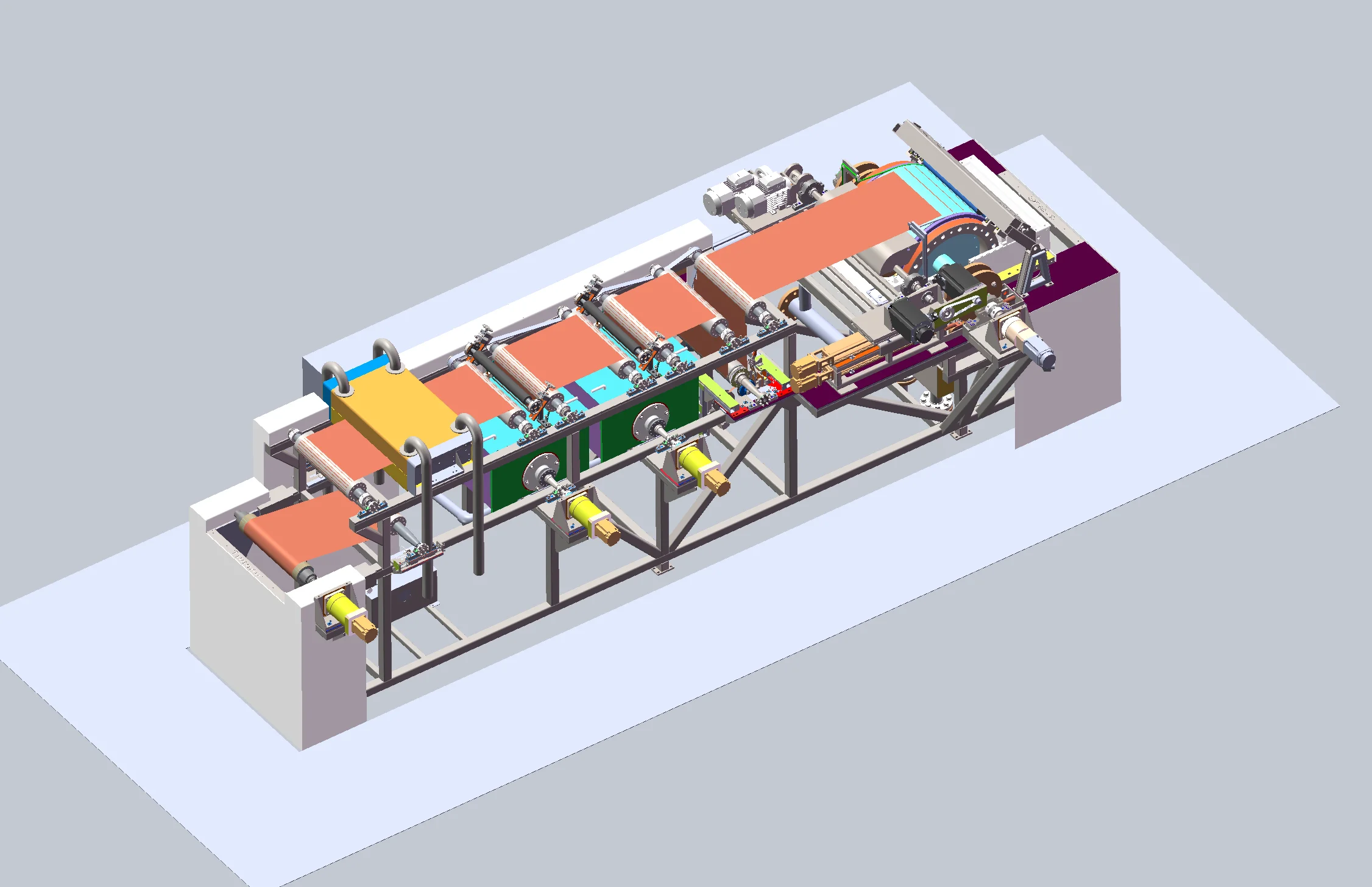

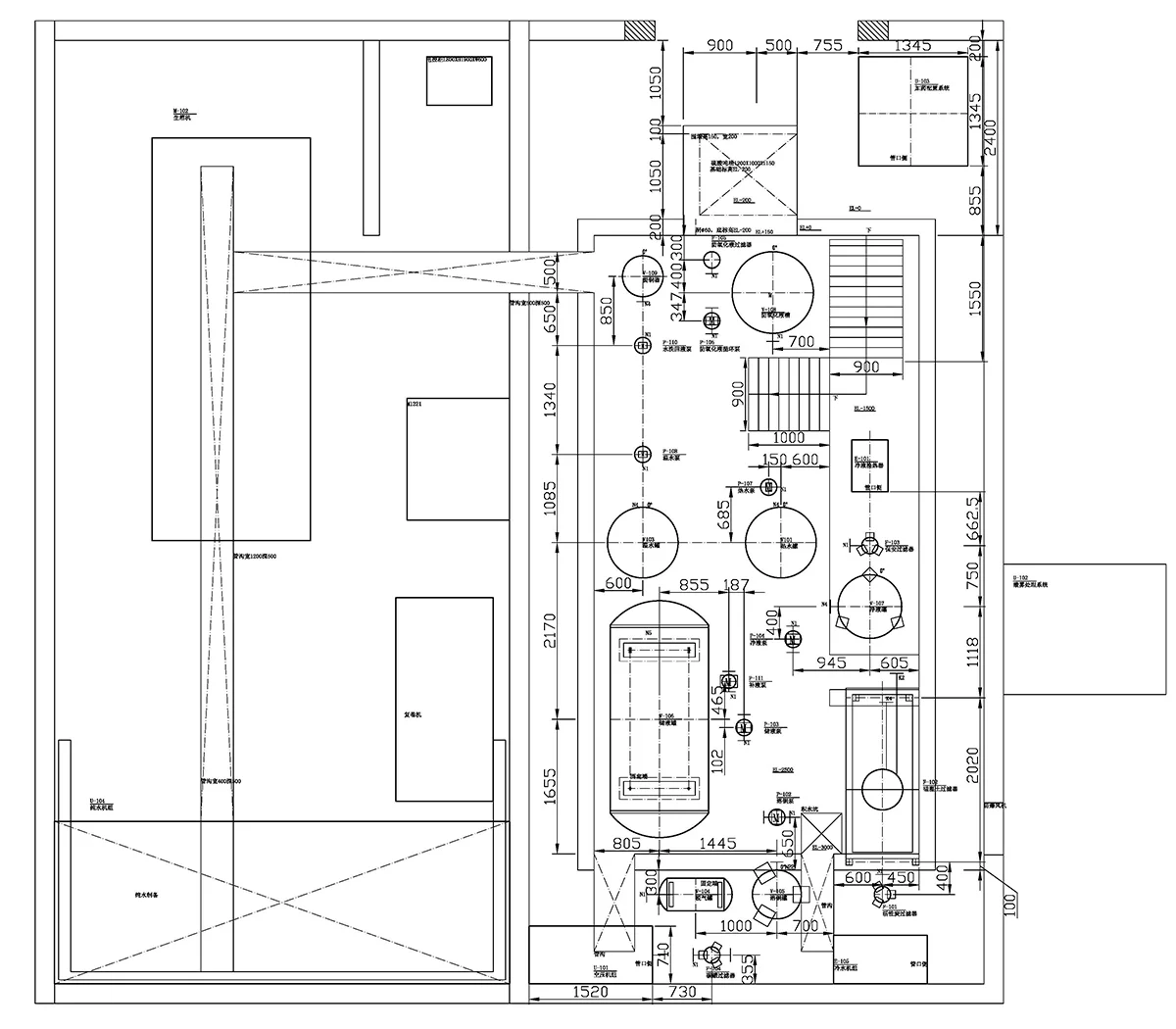

An electrolytic copper foil test line is a specialized, small-scale production system designed for sampling, evaluating, and optimizing foil production parameters. It replicates the core processes of full-scale electrolytic copper foil manufacturing but at a reduced capacity that enables rapid experimentation and adjustment.

These test lines allow engineers to analyze current density behavior, deposition uniformity, crystallization patterns, polishing effects, and coating performance. By simulating real production within a controlled environment, the test line provides precise data that supports consistent quality improvement.

Timonic, with its strong focus on new energy lithium battery material equipment, has developed advanced test line systems that offer high accuracy, stability, and intelligent monitoring—making them valuable tools for both R&D institutions and foil manufacturers.

Importance in Enhancing Production Stability

Production stability is essential in the copper foil industry, where even fractional deviations can lead to defective batches. An electrolytic copper foil test line helps manufacturers identify and correct issues before scaling up the process.

Through continuous testing, engineers can verify electrolyte composition, electrode condition, and additive performance. They can also experiment with new formulas or processing techniques to enhance foil characteristics such as elongation, tensile strength, surface roughness, and peel strength.

With Timonic’s technologically advanced test lines, companies can streamline their workflows, reduce waste, and ensure that every production run adheres to strict quality standards.

Driving Innovation in High-Precision Foil Development

As industries push toward ultra-thin foil—some as thin as 4–6 microns—innovation becomes increasingly important. Test lines accelerate this innovation by providing a safe, efficient platform for research.

Manufacturers can simulate future product demands, test new foil compositions, or optimize processes for next-generation batteries and electronics. Test lines also support the development of specialized copper foil types such as low-profile foil, high-strength foil, and ultra-thin battery foil.

Timonic’s continuous investment in R&D brings cutting-edge solutions to the field, empowering manufacturers to adapt quickly to market changes and technological advancements.

Ensuring Product Quality and Customer Confidence

One of the most significant advantages of using an electrolytic copper foil test line is the boost in product reliability. Customers, especially in battery and PCB manufacturing, demand precision, consistency, and performance.

By refining production parameters through extensive testing, manufacturers can deliver copper foil that meets strict specifications. This increases customer satisfaction, strengthens supplier credibility, and enhances competitiveness in a rapidly expanding industry.

Timonic supports these goals by offering equipment designed for high reproducibility and intelligent data tracking, enabling companies to maintain strong quality control from development to mass production.

Supporting Sustainable Manufacturing Practices

Sustainable production is becoming a priority across the copper foil and battery industries. Test lines help minimize environmental impact by allowing manufacturers to fine-tune processes before full-scale implementation.

Optimized electrolyte usage, energy-efficient deposition parameters, reduced scrap rates, and lowered chemical waste are all direct benefits of thorough testing. With sustainability expectations rising, test lines play a crucial role in achieving greener production without compromising quality.

Timonic’s solutions emphasize energy efficiency and environmental responsibility, aligning with global sustainability goals in the new energy sector.

Conclusion

An electrolytic copper foil test line is far more than a miniature production system—it is a pivotal tool for ensuring quality, promoting innovation, and optimizing efficiency in high-precision copper foil manufacturing. As industries demand increasingly advanced materials, the importance of reliable testing and research platforms continues to grow.

Timonic, dedicated to the R&D and production of equipment for new energy lithium battery materials, provides the advanced technology that drives the evolution of copper foil production. By adopting cutting-edge test line equipment, manufacturers can achieve superior performance, higher stability, and greater confidence in every sheet of foil they produce.

In an industry where precision defines success, the electrolytic copper foil test line stands as a foundation for progress, quality, and long-term competitiveness.

Solving Common PCB Polishing Challenges with Titanium Cathode Drum PVA Technology

http://www.timonic.com.cn

Timonic -

AuthorPosts

- You must be logged in to reply to this topic.