- This topic is empty.

-

AuthorPosts

-

2025-01-06 at 5:56 pm #5655

Heat exchangers are integral components in a vast array of industries, playing a pivotal role in energy transfer between different fluids. From chemical processing to power generation, the design and material choice of a heat exchanger can significantly impact the performance, efficiency, and safety of industrial operations. Among the many materials used for constructing heat exchangers, zirconium has emerged as one of the most robust and reliable choices. Zirconium heat exchangers, in particular, are gaining attention due to their superior corrosion resistance, high-temperature performance, and suitability for highly aggressive environments. In this article, Qiwei will delve deep into the key benefits that zirconium heat exchangers bring to industries requiring high-performance thermal management solutions.

What is a Zirconium Heat Exchanger?

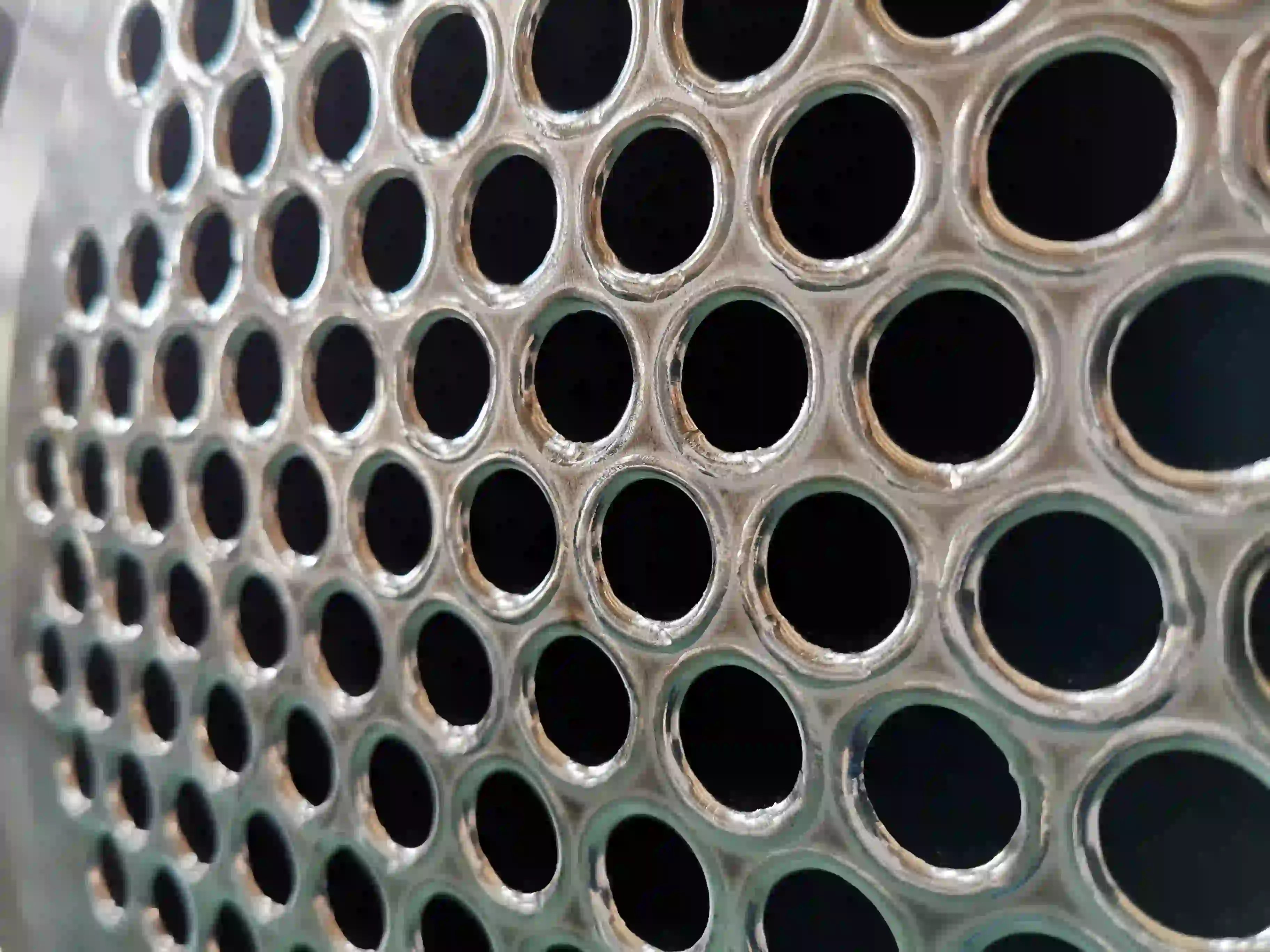

A zirconium heat exchanger is a type of heat exchanger designed to transfer thermal energy between fluids, utilizing zirconium as the primary material for its construction. Zirconium, a transition metal, is known for its exceptional resistance to corrosion, particularly in harsh environments that involve acidic or alkaline fluids at high temperatures. Unlike traditional heat exchangers made from materials like stainless steel or titanium, zirconium heat exchangers are specifically engineered to withstand the most extreme chemical conditions. The remarkable corrosion resistance of zirconium is what sets it apart from other materials, especially in processes involving aggressive acids such as hydrochloric acid, sulfuric acid, and other highly corrosive substances. Zirconium heat exchangers are typically used in industries such as chemical processing, nuclear power, pharmaceuticals, and petrochemical sectors, where the integrity of heat exchange systems must be maintained even in the presence of highly corrosive and high-temperature fluids.

Key Benefits of Zirconium Heat Exchangers

1. Exceptional Corrosion Resistance

One of the standout features of zirconium is its superior resistance to corrosion, particularly in highly acidic or alkaline environments. The unique properties of zirconium make it ideal for handling aggressive chemicals and high-temperature fluids, especially in environments where traditional materials would degrade rapidly.Zirconium forms a stable, protective oxide layer on its surface, which shields the underlying material from further corrosion. This oxide layer helps maintain the integrity of the heat exchanger over time, even in environments where conventional materials such as stainless steel or copper might fail. The corrosion resistance of zirconium is particularly valuable in chemical reactors, acid concentration units, and other industrial applications where the fluid media could cause severe corrosion to other materials.

2. High-Temperature Performance

Zirconium heat exchangers are known for their ability to withstand high operating temperatures without losing structural integrity. Unlike many metals that soften or become brittle under elevated temperatures, zirconium maintains its mechanical properties even in extreme heat conditions. This makes it an excellent choice for high-temperature processes where heat transfer efficiency is critical. In industries such as nuclear power generation, zirconium's high-temperature stability is of paramount importance, as it ensures that the heat exchanger can continue to operate efficiently even at temperatures that would cause other materials to degrade. Zirconium's ability to perform in both high-temperature and chemically aggressive environments makes it a go-to material for demanding heat exchange applications.

3. Enhanced Durability and Longevity

The combination of corrosion resistance and high-temperature stability translates into extended service life for zirconium heat exchangers. Due to the material’s remarkable durability, these heat exchangers often outperform their counterparts made from stainless steel or titanium, particularly in challenging environments where other materials would require frequent maintenance or replacement. This durability is crucial in industries such as pharmaceuticals and petrochemicals, where unplanned downtime can be costly. Zirconium heat exchangers can operate for years without requiring significant maintenance, thus providing a long-term, cost-effective solution for industries that depend on reliable heat transfer processes.

4. Minimal Contamination Risk

In some industrial applications, the risk of contamination from the heat exchanger materials into the process fluid is a serious concern. Zirconium is non-reactive and does not leach into the fluids it comes into contact with, minimizing the risk of contamination. This feature is especially important in sensitive processes like pharmaceutical manufacturing or food processing, where the purity of the product is paramount. Additionally, zirconium's inert nature reduces the risk of chemical reactions between the heat exchanger and the process fluids, which helps maintain the quality and integrity of the final product. As a result, zirconium heat exchangers are ideal for applications that require high purity standards and stringent contamination control.

5. Resistance to Stress Corrosion Cracking

Zirconium exhibits exceptional resistance to stress corrosion cracking (SCC), a type of damage that occurs when a material is subjected to tensile stress in the presence of a corrosive environment. In many industries, SCC can lead to catastrophic failures in heat exchangers made from less durable materials. Zirconium’s ability to resist this form of damage ensures that heat exchangers made from this material maintain their performance even under high-stress conditions, providing a higher level of reliability in critical applications.

Zirconium heat exchangers are a vital component in industries where high-performance thermal management is required in aggressive environments. Their unparalleled corrosion resistance, high-temperature capabilities, and durability make them ideal for applications involving corrosive chemicals, extreme temperatures, and critical processes. Whether used in chemical processing, nuclear power, petrochemicals, or pharmaceuticals, zirconium heat exchangers continue to prove themselves as a reliable and cost-effective solution for a wide range of industrial needs. As industries continue to demand higher efficiency, reliability, and safety, zirconium heat exchangers will remain a top choice for those seeking the best in heat exchange technology.

https://www.tnztn.com/Zirconium-Heat-Exchanger

http://www.tnztn.com

Wuxi Qiwei Nonferrous Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.